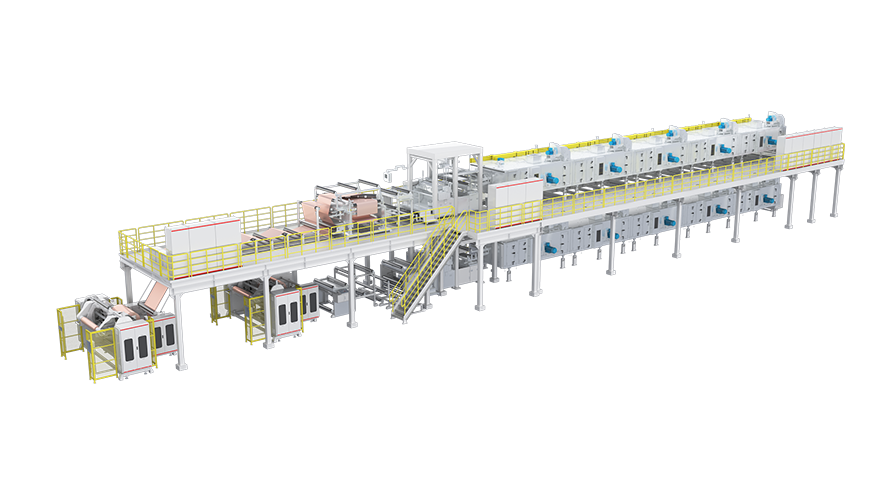

The transition to renewable energy and the growing demand for electric vehicles have heightened the importance of efficient lithium battery production. Companies across various sectors are increasingly investing in automation equipment to enhance productivity, reduce costs, and meet stringent quality standards. One standout player in this market is the double-layer super-E coating machine, which revolutionizes electrode production through innovative design and technology.

Electric Vehicle Manufacturing

The electric vehicle (EV) industry has emerged as a major beneficiary of lithium battery automation equipment. With the rising popularity of EVs, manufacturers are under pressure to produce high-quality batteries at a faster pace. The use of advanced battery electrode coating machines helps streamline production, enabling companies to achieve superior coating uniformity and thickness control. This directly translates to improved battery performance, making it a pivotal component in automobile manufacturing.

Renewable Energy Solutions

Solar energy storage systems rely heavily on efficient lithium-ion batteries for optimal performance. Automation equipment like the battery electrode coating machine allows renewable energy providers to increase production efficiency while maintaining high safety standards. By utilizing sophisticated coating machines, these companies can produce batteries that offer longer lifespans and enhanced energy density, which are crucial for meeting the demands of solar energy applications.

Consumer Electronics

The consumer electronics sector is another prominent industry benefiting from lithium battery automation. As devices become more energy-dependent, the need for reliable and efficient batteries grows. Coating machines play a vital role in manufacturing lithium batteries used in smartphones, laptops, and other gadgets. By adopting automated systems, manufacturers can significantly reduce production time and costs while ensuring consistent quality in battery outputs.

In summary, industries such as electric vehicle manufacturing, renewable energy solutions, and consumer electronics stand to gain immensely from advancements in lithium battery automation equipment. Investing in innovative technologies, like the Double-Layer Super-E Coating Machine from Yinghe, not only enhances operational efficiency but also positions businesses to excel in a competitive marketplace. The future of battery production is bright, and those who embrace automation will lead the charge.